UX Design Project - PetSafe Brands

Optimizing the fence installation process for technicians to increase productivity and profit

Imagine you are the lead user experience designer working on a product that uses new technology to keep pets safe at a company that is an established leader in the pet containment and pet tech industry.

Your company has several patented methods and technologies they use to keep pets safe within invisible fences; however, a few of these patents’ terms are about to end. Because these methods are about to become public domain for any competitor to use, your company is pursuing new methods and technologies for pet fence containment.

While performing the discovery work for this new product, you uncover inefficiencies and employee pain points that seem to have relatively easy solutions that would save the company time and money in their service business model.

Although sharing these opportunities to improve employee workflows and increase the company’s revenue in this business model is not directly part of your work on this project, you take the initiative to share your learnings with leadership.

The Context

What I Did

-

Observed the Installation

I rode along with a technician installing a connected, in-ground fence to observe their process as part of research for a new product.

-

Documented the Process

On the ride-along, I took notes, asked the technician questions, and documented the process and steps involved in the installation.

-

Shared My Learnings

While observing, I noticed potential areas for improvement. I shared my observations to improve the technician experience and increase efficiency.

Key Project Takeaway

Observing this potential for improvement early on in the project allowed me to ideate on alternative solutions, test the suggestions, strategize a plan for change, and share the recommendations with stakeholders resulting in thoughtful conversation rather than a quick, reactive decision.

Observing the Install

I observed a connected, in-ground fence installation. The technician I was shadowing was training a new technician–allowing me to observe the process and learn with the new technician.

Steps to Install

The technician went through his normal process of installing and setting up a fence while I observed and asked clarifying questions.

He shared his thoughts and experiences on both the setup process and the post-install fence functionality.

We candidly discussed his likes and dislikes in addition to the complications he had experienced when installing this particular fence.

I observed and heard several pain points he experienced daily that seemed to have easy solutions.

Documenting the Steps

After observing the installation, I compiled my notes into a process flow document to share with the project team and business stakeholders.

Reviewing My Notes

The goal of the ride-along was to understand the process a technician goes through to install a fence so I could design a setup experience for a new wireless fence that would account for their process and fit their mental model.

I flagged pain points while taking notes on my ride-along but noticed several more when putting together the process document and talking through the findings with my team.

I decided since efficiency was a major area of concern for our project, I should share opportunities I identified to improve efficiency with current products on the market.

Fence Installation Flow

After observing the installation, I documented the steps and process flow.

Identifying Major Areas of Improvement

Overall, I identified several key areas in which we–the company–could make the process easier for the technicians and reduce the time spent at each install.

-

Creating the Customer Account

The Technician was responsible for creating the customer’s account using information the Consultant had already entered into the database.

This process was duplicate work and created the opportunity for human error to add complexity–ie. entering email addresses incorrectly impacting customer login and adding troubleshooting time to discover the error.

-

Using Multiple Sources of Truth

Creating the customer account and associating the new system with that account was completed using both the Technician app and the back-end database site.

This led to duplicate information, extra effort when entering and editing information, and additional cognitive load for the Technician.

-

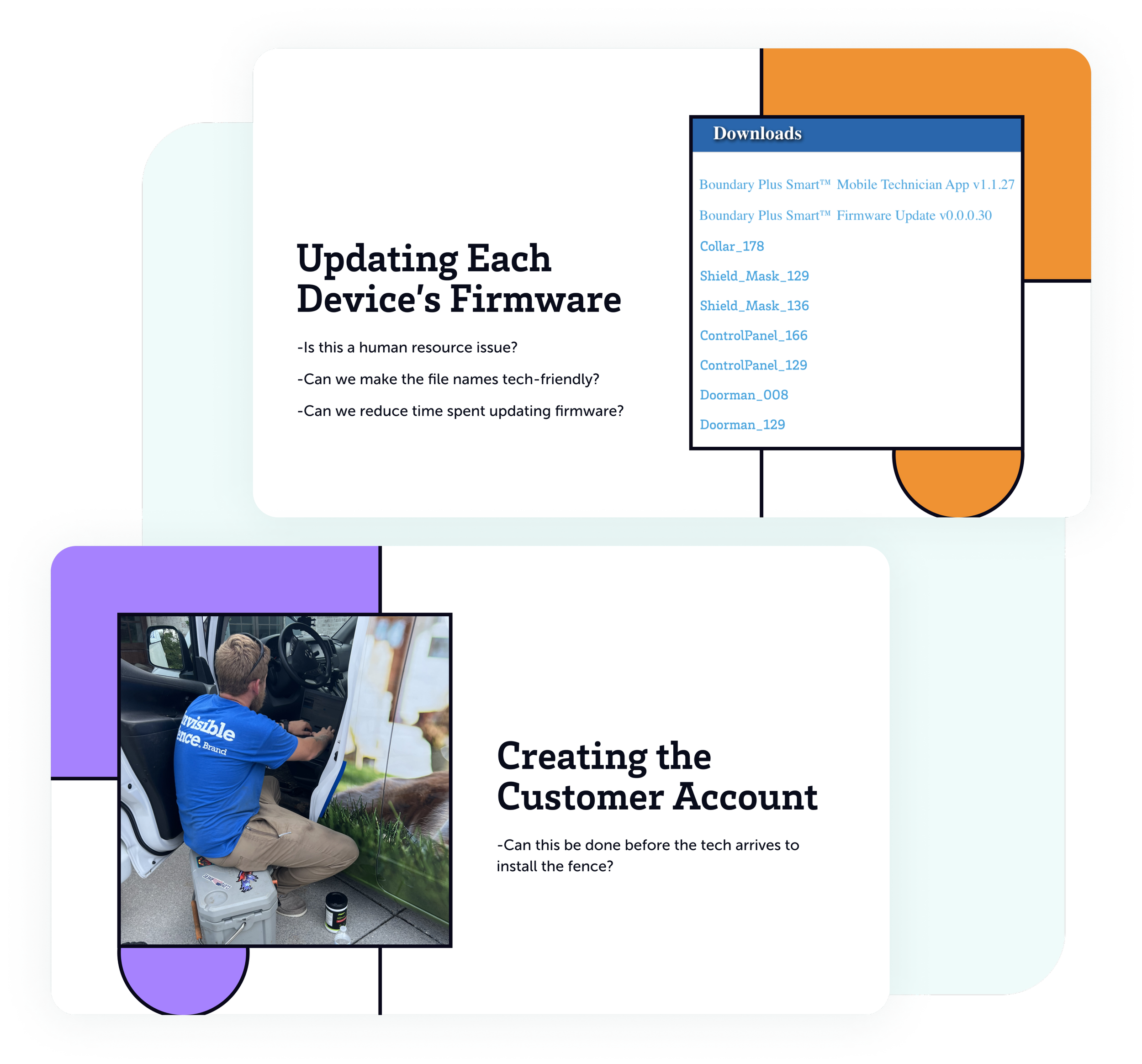

Updating the Firmware

This intensive process required the Technician to connect directly to each device with a Bluetooth dongle, check which firmware was on the device, check the most recent firmware file list, download the new firmware file to their computer if necessary, upload the new file to the device, and repeat for each device in the system.

Depending on LTE signal strength, this process could take up to 3 hours for the Technician to update every device’s firmware.

-

Scanning Product Barcodes

To track inventory, the Technician was supposed to scan the barcodes on each device in the system and associate each device with the customer’s account.

These barcodes were important for tracking inventory and sales as well as keeping enough product in the warehouse to fulfill all customer fence requests.

Next Steps

After identifying the areas of improvement and why they were opportunities to improve the installation experience for the technician, I ideated on solutions to share with leadership.

Sharing the Learnings

I created a brief presentation highlighting the technician's pain points adding to installation time, questions to learn more about potential solutions, and suggestions for possible solutions.

Meeting with Leadership

I met with members of the business leadership team to share my findings and suggestions.

Framing the presentation as observations I found while researching for a project, I shared what I saw and heard from the technician.

We discussed the learnings and answered any questions they had. I got answers to my questions that influenced the solutions I presented to them.

Suggesting Solutions

I presented some potential solutions for the identified pain points as part of the presentation. My goal was to suggest simple, easy solutions that would be quick to implement showing immediate results and saving the company time and money.

-

Creating the Customer Account

I suggested having the Consultant or Customer Care agent create the customer account in the system when setting up the appointment for the fence installation saving the Technician time and improving the accuracy of information.

-

Using Multiple Sources of Truth

I suggested combining the two systems/apps the Technician has to use to set up the customer account and register the new fence saving the Technician time, improving the accuracy of the information, and minimizing the effort to update information in multiple places.

-

Updating the Firmware

I suggested several potential solutions. First, have an employee working in the office check and update the firmware of the devices when waiting for clients.

Second, change the file names to be Technician-friendly. I researched and learned the names shown did not need to be as complicated as they were.

Third, consider providing Technicians with hotspots to guarantee access to the internet and increase the speed of the updates.

-

Scanning Product Barcodes

I suggested linking the devices’ unique ID to the barcode to remove scanning the barcodes as a necessary part of the process and ensure the products would be tracked for inventory.

For the product we were working on, I proposed that connecting to the device via Bluetooth could have a similar action tracking the products automatically and removing the potential for human error and additional steps during setup.